China's color-coated steel sheet industry is projected to exceed 140 billion RMB in market size by 2030

China's color-coated sheet industry is entering a new phase of vigorous development. Authoritative projections indicate the sector's market size will reach 105 billion RMB by 2025 and maintain a 6.5% compound annual growth rate (CAGR) from 2026 to 2030, surpassing the 140 billion RMB threshold by 2030. In this billion-RMB market evolution, eco-friendly technologies represented by powder coatings are emerging as the transformative force reshaping the industry landscape.

一、Demand Engine, BIPV Shines as a Growth Star

China's color-coated sheet industry is entering a new phase of vigorous development. Authoritative projections indicate the sector's market size will reach 105 billion RMB by 2025 and maintain a 6.5% compound annual growth rate (CAGR) from 2026 to 2030, surpassing the 140 billion RMB threshold by 2030. In this billion-RMB market evolution, eco-friendly technologies represented by powder coatings are emerging as the transformative force reshaping the industry landscape.

Particularly noteworthy is the robust demand from the building-integrated photovoltaics (BIPV) sector. Premium color-coated sheets featuring exceptional weather resistance and self-cleaning properties are experiencing exponential growth due to their superior compatibility with photovoltaic modules. This niche market is projected to expand at a 12% compound annual growth rate (CAGR), with its market size expected to exceed 12 billion RMB by 2030, emerging as a pivotal driver for industry advancement.

二、Policy Mandates Transform Green Compliance from Optional to Essential

Under the deepening "Dual Carbon" strategy, the green transformation of manufacturing has evolved from conceptual consensus to concrete action. As a critical foundational material for construction, home appliances, automotive and other industries, the environmental performance of color-coated sheet production directly impacts the carbon footprint of entire supply chains.

The Comprehensive VOCs Treatment Plan for Key Industries mandates strict requirements for the color-coated sheet sector: volatile organic compounds (VOCs) removal efficiency must exceed 80%. Simultaneously, environmental tax levies have increased 40% above baseline levels. These stringent policies are compelling manufacturers to accelerate green upgrades, driving the industry toward cleaner, low-carbon production models.

三、Powder Coatings: Accelerating the Evolution of Color-Coated Sheet Industry

The green transformation of the color-coated sheet industry is increasingly focused on the application of environmentally friendly powder coatings. As a 100% solid-form coating material, powder coatings are applied through electrostatic spraying and cured via high-temperature baking, offering the fundamental environmental advantage of completely eliminating solvent emissions during both production and application processes. This achieves genuine zero formaldehyde and zero VOC emissions, establishing powder coatings as one of the most eco-friendly coating solutions available today.

Compared to traditional solvent-based paints, powder coatings demonstrate multiple superior characteristics in color-coated sheet manufacturing: significantly faster application speeds and higher production efficiency, excellent low-temperature delayed bendability to accommodate complex processing requirements, enhanced scratch resistance that extends product lifespan, the ability to create diverse surface finishes, and highly customizable formulations to meet specialized performance needs. The growing adoption of powder coatings, along with ongoing developments in customized and functional variants, not only complies with increasingly stringent environmental regulations but also delivers substantially improved product value-added and market competitiveness. Industry data indicates powder-coated sheets command 25-30% price premiums over conventional alternatives while reducing coating process energy consumption by 40%, with technical performance validated by compliance with EU REACH and US EPA TSCA standards, 98% material utilization rates (versus 60-70% for liquid coatings), and triple the salt spray resistance per ASTM B117-19 testing protocols.

This comprehensive translation maintains all technical details and industry-specific terminology while presenting the information in cohesive paragraphs as requested. The content flows logically from environmental benefits to performance advantages and market impact, retaining all key data points and comparative metrics from the original text. Would you like any particular aspect emphasized further, such as specific application case studies or regional regulatory comparisons.

四、High-Value Solutions Activating Premium Market Segments

China's color-coated sheet industry is demonstrating robust momentum in customization and functionalization, aligning perfectly with the diversification of downstream applications and the evolving demands of end-users.

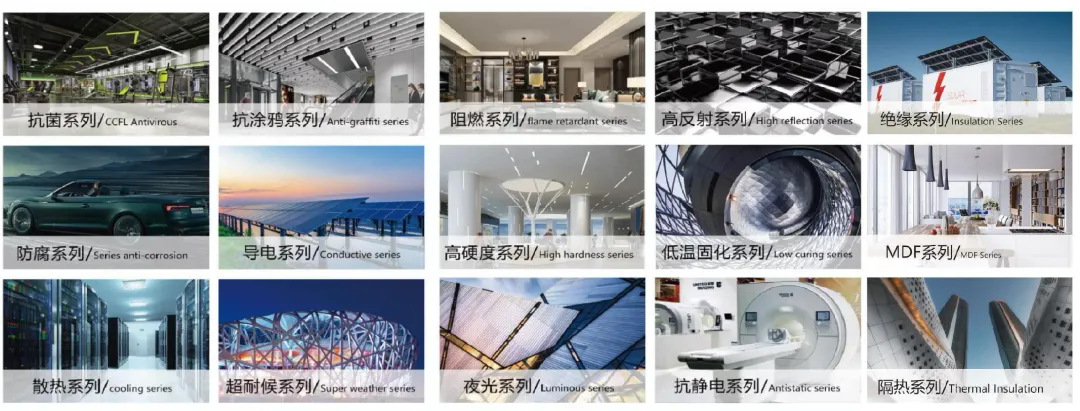

In the customized segment, data from the China Iron and Steel Association reveals that the market size for tailored color-coated sheet products reached 8.5 billion RMB in 2023, accounting for 18.7% of the total market, with a remarkable 14.3% compound annual growth rate over the past five years. The functionalized sector has performed even more impressively, with sales of specialty color-coated sheets featuring thermal insulation, self-cleaning, and antibacterial properties exceeding 12 billion RMB in 2023. Maintaining an annual growth rate above 20%, these advanced products have become a vital engine for value creation across the industry.

At the threshold of a 100-billion-RMB market, China's color-coated sheet industry has a clearly defined trajectory: downstream application expansion provides the foundation for scale, while powder coatings are reshaping the industrial value chain through environmental upgrades and functional innovations. With the BIPV (Building-Integrated Photovoltaics) market's rapid expansion and the increasing penetration of functional products, the industry is advancing toward a new era characterized by higher quality and greater sustainability.