Groundbreaking Advance in Light-Absorbing Coatings Accelerates Multi-Sector Innovation

The light-absorption capacity of materials is pivotal across multiple industries. However, untreated conventional materials typically exhibit low light-absorption rates, failing to meet the demands of high-tech, high-value sectors such as:Aerospace,Photovoltaic power generation,Automotive manufacturing,Architectural decoration,Premium home appliances

The advent of light-absorbing powder coatings has broken through these limitations. Through innovative material formulations and advanced coating technologies, these coatings endow materials with high light-absorption properties, redefining material-light interactions and accelerating progress across industries.

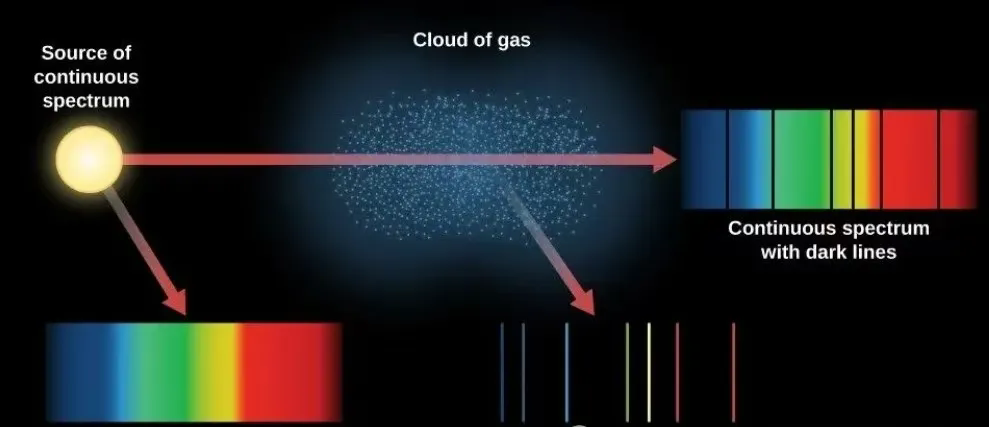

As the pursuit of efficient and precise light-energy utilization intensifies, groundbreaking advances continue in light-absorption technology.Light-absorbing materials are a class of substances capable of:Absorbing photons within specific wavelength ranges.Converting light energy into other forms (e.g., thermal, electrical energy).Among these, light-absorbing coatings represent a thin-film subtype designed for surface applications.

Principles of Light Absorption

The light-absorption performance of materials primarily depends on four critical factors:Elemental Electrical Properties – The inherent electronic characteristics of constituent atoms;Molecular Architecture – Precise design of chemical bonds and functional groups;Atomic Arrangement – Crystalline or amorphous structural organization;Surface Microstructure – Nano/micro-scale topological features.By strategically engineering these parameters—particularly through targeted chemical composition and molecular structure design—materials can achieve wavelength-selective absorption, enabling customized solutions for specialized applications.

二、The Value of Light-Absorbing Powder Coatings

As a functional coating with unique optical properties, light-absorbing powder coatings typically contain specialized light-absorbing pigments or additives (such as carbon black, iron oxide black, etc.). Their molecular structure interacts with photons to effectively absorb light across various wavelengths, converting light energy into thermal or other forms of energy. This high-efficiency light-absorption capability plays a crucial role in applications requiring reduced light reflection or enhanced energy absorption. Consequently, light-absorbing powder coatings are widely used in industries such as aerospace, solar photovoltaics, automotive manufacturing, architectural decoration, and home appliance production.

When applied to building curtain walls, light-absorbing powder coatings can reduce the intensity of reflected light on the curtain wall surface, thereby alleviating urban light pollution. Additionally, they can endow the curtain wall with a delicate and premium texture, meeting environmental requirements while promoting the advancement of urban architectural aesthetics.

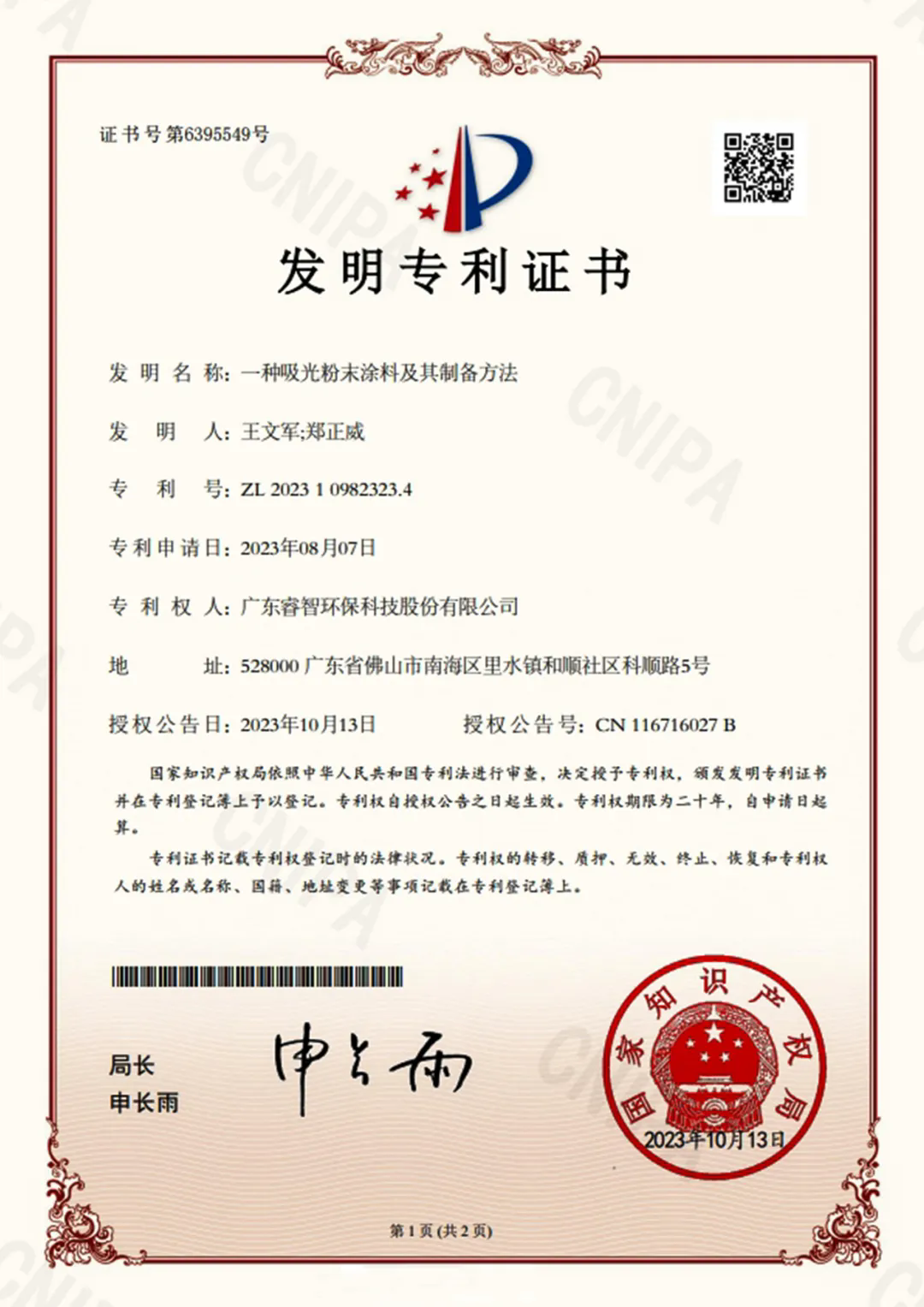

三、WISELY Light-Absorbing Powder Coatings

Developed based on patented technology (Patent No.: ZL 2023 10982323.4), WISELY light-absorbing powder coatings are formaldehyde-free and zero-VOC. Through specialized formulations and advanced manufacturing processes, they effectively address the limitations of conventional light-absorbing coatings—such as excessive thickness, poor adhesion, easy peeling, inferior weather resistance, and harmful substance emissions. These innovative coatings deliver exceptional stability, high strength, superior toughness, and outstanding light absorption, establishing a groundbreaking solution for light-absorbing coating applications.

Ultra-High Light Absorption:With an absorption rate reaching 99.07%, our coating efficiently captures light across UV to infrared spectra, delivering exceptional value for optical devices and solar energy applications.

Superior Strength & Toughness:Engineered with balanced mechanical properties, it achieves:Impact resistance: 62.43 kg/cm;Wear resistance: 3.25 L/μm;Maintaining long-term stability even under extreme conditions.

Advanced Hydrophobicity:Featuring a 139.8° water contact angle, the coating:Enhances self-cleaning capability;Reduces dust/contaminant adhesion;Extends service life through improved corrosion resistance

Eco-Efficient Production:Our formaldehyde-free, zero-VOC coating combines:Green manufacturing compliance;High-yield production scalability;Industry-leading process efficiency

The Future of Light-Absorbing Materials

As technology advances, we anticipate revolutionary developments in photonic materials. Innovations like WISELY coatings will continue to redefine performance standards across industries, driving society toward an era of unprecedented efficiency and sustainability.